This is the primary reason that nanotube paint or suspensions are difficult to make and build viscosity quickly. The volumetric ratio R for nanotubes of this aspect ratio is 4x10 -5 vol%, which is less than 1 milligram per liter! (see Ref 1) At any greater concentration, the nanotubes will intrude upon each other’s hydrodynamic spheres and hinder rotation.

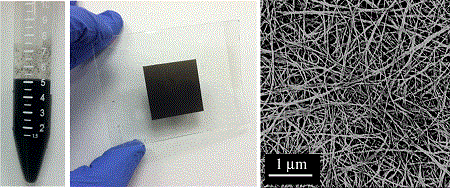

For a nanotube with an aspect ratio of a = L/d, the ratio (R) of the nanotube's actual volume V actual = (0.785 a d 3) to the volume of the swept out sphere V sphere = (0.523a 3d 3) reduces to: R = 3/(2a 2)Īspect ratios for carbon nanotubes are ~2000, For example, MWNT are often 20 microns long and 10nm diameter, and SWNT are often 2 micron long and 1nm diameter. This rotation creates a large effective hydrodynamic radius, and each nanotube sweeps out a spherical volume, as shown below. When particles with a large aspect ratio (like carbon nanotubes) is dispersed in a solvent fluid, they will rotate, due to Brownian motion or in the presence of a velocity gradient (flow). It will be useful to start by modeling the nanotubes as rigid rods in a liquid suspsension, to determine how far apart they may be for a given concentration. This brief is an introduction to nanotube paints and suspensions, and explains how they are stabilized and what concentrations are feasible. Nanotubes are not solubilized, rather they are suspended as individual particles in the fluid, like an ink or paint. Stabilization, ink, paint, stable, dispersion, disperseĬarbon nanotube suspensions can be made in a number of ways, and with a number of fluids. Suspension, solution, carbon nanotube, gram per liter, g/l, surfactant, solvent, PECVD-MWCNT suspensions harvested from aligned arrays.Shipping charges are prepaid and added to an invoice.Īpplicable duties and taxes are paid separately upon custom clearance. If you need your suspension sooner, please email us directly at us custom suspension requests to on the pricing below for more information or to order online Please note Suspensions are made to order and can sometimes take a week. These typically involve the use of surfactants to assist in stabilization.įor our line of inkjet printing inks (Nink) based on nanotubes, click here. Separately we offer suspensions in various solvents that are made from pristine nanotubes. Suspensions and paints having different concentrations, special solvents, or large volumes are available send a request by email. These can be inkjet printed thru Fuji Dimatix printers, or other printers. Below the product offerings is a review, covering details of preparing and working with suspensions or inks aka (Nink). These nanotube paint - like suspensions are prepared from our standard single and multiwall carbon nanotubes, and are stable for months in our lab. We offer suspended, carboxylated nanotubes in water, ethanol, acetone or dimethylformamide (DMF). After washing the nanotubes to remove excess acid, they may be dispersed. To create carboxyl (COOH) functional groups on the sidewall of the carbon nanotubes, we treat them in a mixture of hot nitric & sulfuric acids. Lower concentrations can be achieved in a number of other solvents that can be used as a nanotube paint, ink, etc. Our carboxylation process yields nanotubes with a strong negative charge that keeps them suspended in water at up to 2 gram/liter concentrations without the presence of a surfactant.

CARBON NANOTUBE DISPERSIO NINK FREE

To reduce the size of the bundles and stabilize the solution, an ultrasonic horn with an ultrasonic bath were combined as mechanical stress for CNT dispersion, and some chemicals such as sodium dodecyl sulfate (SDS)-a surfactant, N-methyl-2-pyrrolidone (NMP)-a solvent, or chitosan were used to meet our requirements.Carbon nanotube suspensions, paint, & ink formulationĬOOH Functionalized, Surfactant Free Carbon Nanotube Suspensions The size of the head printer nozzles required very small particles, about a few micrometers, in order to be able to print on the sensitive position of the antenna. Our purpose was to reduce as small as possible CNTs bundles, in order to realize ink to print on an RFID antenna. However, due to their entanglement state, their size and the different interacting forces between nanotubes bundles present at nanometric scale, CNTs debundling is very hard to achieve, requiring specific equipment and chemicals. The use of carbon nanotubes (CNTs) in radio frequency identification (RFID) applications offers a very large range of possibilities to exploit the incredible properties of CNTs.

0 kommentar(er)

0 kommentar(er)